From sequence to antibody in 5 weeks – with the highest quality standards

Low levels of endotoxin <1EU/mg

The production of recombinant antibodies is a method used to generate antibodies in a laboratory setting, by combining genetic material from different sources. It relies on the process called recombinant antibody expression1.

Recombinant manufacture enables the production of high-quality, homogeneous antibodies with specific properties and functions that can be tailored to different applications. Recombinant antibodies can be designed to target specific epitopes and engineered to improve their stability, specificity, and affinity.

The fast production and high quality of recombinant monoclonal antibodies has qualified them as one of the most important tools in biotechnology and the production of biotherapeutics.

In this article, we will discuss the process of recombinant antibody production, its applications in various fields, and its advantages and limitations compared to traditional antibody production methods. We will also explore the future directions in the field, highlighting the advancements in technology and emerging applications.

Subscribe to our Newsletter

Get all the latest updates, and learn about our advancements in antibody production.

Subscribe now

evitria has been focusing on recombinant antibody production service since 2010 and has gained a lot of experience in this field with more than 120,000 production runs, which in turn has enriched customers all over the world.

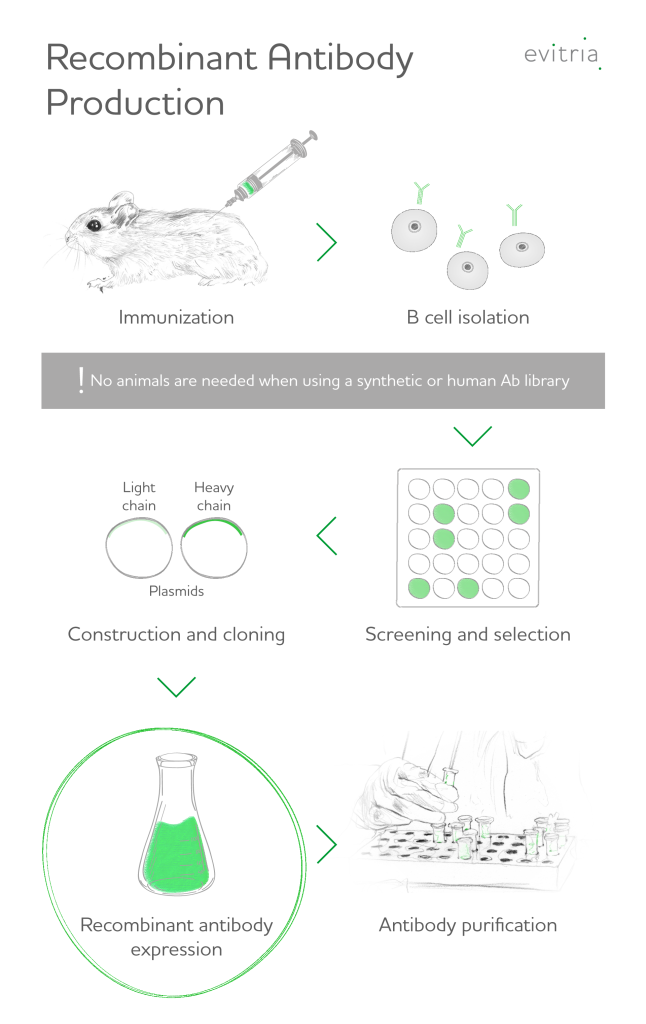

Recombinant antibody production is a technique that involves the use of genetic engineering to produce specific antibodies in vitro. This method typically involves the use of genes from different sources, often obtained from B cells of an immunized donor organism. These genes are cloned and then combined to create hybrid antibodies with unique properties.

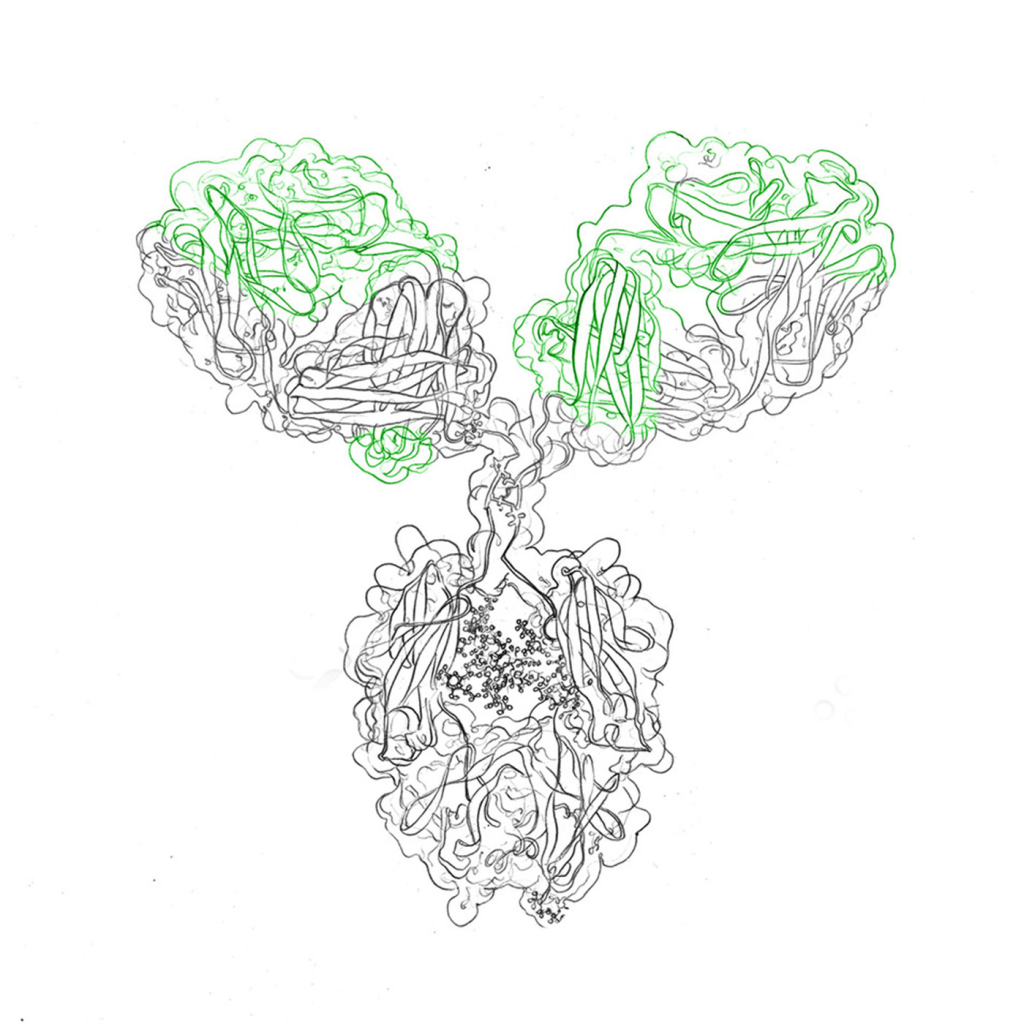

Antibodies are proteins, specifically immunoglobulins (such as IgG), that are produced by B cells in response to foreign substances, such as viruses or bacteria. Each antibody is composed of two heavy chains and two light chains, and each chain has a constant region and a variable region. The variable regions are responsible for recognizing and binding to specific targets, known as antigens.2

Read more on antibody production in B cells

Recombinant antibody production involves cloning genes encoding for the desired antibody and expressing them in bacterial or mammalian cell expression systems. The genes encoding the heavy and light chains of a desired antibody are cloned into an expression vector, which is then introduced into host cells via transfection. The host cells then produce and secrete the antibody, which can be purified and used for various applications, such as diagnostic assays or therapeutic treatments.

Compared to traditional methods of antibody production, recombinant antibody production offers several advantages. For instance, recombinant antibody technology enables the production of large quantities of homogeneous antibodies that can be easily optimized for specific applications. Furthermore, it allows for the generation of humanized or fully human antibodies, which are less likely to trigger an immune response in patients and therefore more suitable for therapeutic use.

Read more: Antibody production services – a comparison

Low levels of endotoxin <1EU/mg

There are several steps involved in recombinant antibody production. These steps typically include:

In the next chapters we will dive deeper into Antibody Engineering and Optimization as well as into the expression process.

Antibody engineering and optimization is a critical step in recombinant antibody production, as it enables the generation of antibodies with improved properties for various applications. This step typically involves the use of genetic engineering techniques to modify the sequence and structure of the antibody molecule.

There are several strategies that can be used for antibody engineering and optimization, including:

Antibodies produced in non-human species can elicit an immune response when administered to humans. Antibody humanization involves the modification of the antibody sequence to reduce its immunogenicity and increase its compatibility with the human immune system.

Affinity maturation involves the optimization of the antibody’s binding affinity for its target antigen. This can be achieved by introducing mutations into the antibody sequence that enhance its interaction with the antigen.

Bispecific antibodies are designed to simultaneously bind to two different antigens. This can be achieved through the fusion of two different antibody fragments or the use of bispecific scaffolds.

Read more on bispecific antibody production

Antibody fragments are smaller antibody molecules that retain the antigen-binding properties of the full-length antibody. Antibody fragment engineering involves the modification of the fragment sequence to improve its stability, specificity, and affinity.

Antibody fusion involves the fusion of an antibody molecule with another protein or peptide to create a molecule with new properties. For example, antibody fusion can be used to create immunoconjugates that combine the targeting properties of the antibody with the therapeutic properties of a drug.

Overall, antibody engineering and optimization can greatly improve the efficacy and safety of recombinant antibodies for various applications. By modifying the antibody sequence and structure, it is possible to create molecules with enhanced specificity, affinity, stability, and compatibility with the human immune system.

Recombinant antibodies can be expressed in a variety of systems, including bacteria, yeast, and mammalian cells. The choice of expression system depends on several factors, such as the desired antibody format, expression yield, and post-translational modifications required for functionality. The plasmids used for antibody production can also impact the expression and purification process.

Bacterial expression systems, such as Escherichia coli (E.coli), are commonly used for the production of recombinant antibodies. These systems offer several advantages, such as low cost, high yield, and ease of use. However, bacterial expression systems may not be suitable for the production of antibodies that require post-translational modifications, such as glycosylation.

Yeast expression systems, such as Saccharomyces cerevisiae, are also widely used for the production of recombinant antibodies. These systems offer higher expression yields than bacterial systems and can perform some post-translational modifications, such as disulfide bond formation. However, yeast systems may not be suitable for the production of antibodies that require complex glycosylation patterns.

Mammalian expression systems, such as HEK293 or Chinese hamster ovary (CHO) cells, are preferred cell lines for the production of antibodies that require complex post-translational modifications, such as glycosylation. These systems offer the closest approximation to the native human system, and the resulting antibodies have high biological activity and stability. However, mammalian expression systems are more expensive and time-consuming than bacterial or yeast systems.

Recombinant antibodies can be expressed in cells either transiently or stably. Transient antibody expression involves introducing the antibody gene into cells for a short period, typically using a viral vector, and harvesting the expressed protein after a few days. This method is faster and easier but results in lower expression yields. Stable expression involves integrating the antibody gene into the host cell genome, resulting in higher expression yields but a longer lead time and more complex production process.

After expression, recombinant antibodies may require additional processing steps, such as purification, characterization and validation. Purification can be achieved using a variety of methods, such as chromatography, ultrafiltration, and precipitation, and serves to remove supernatants and various reagents no longer required. At evitria, for instance, we use techniques like affinity chromatography based on protein A and other resins, specialized columns, as well as protein polishing methods like gel filtration and ion exchange chromatography.

Characterization involves verifying the specificity and functionality of the antibody, typically using techniques such as ELISA, Western blotting, and flow cytometry.

Recombinant antibody production offers several advantages over traditional methods such as hybridoma technology, particularly in terms of scalability, reproducibility, and versatility making it a promising alternative to traditional methods of monoclonal antibody production.

While recombinant antibody production offers many advantages in the field of antibody technology, there are also some limitations that must be taken into consideration when choosing a method for antibody production. Nonetheless, the ability to engineer and optimize recombinant proteins has revolutionized the field of antibody generation and opened up new opportunities for research and therapy.

As mentioned above, one of the many benefits of recombinant antibody production is that there is no need for in vivo production steps using animals in the process. While the immunization of a living animal like a mouse or rabbit is part of hybridoma-technology, the process of recombinant antibody production can be carried out without any animals.

Cell lines like Chinese Hamster Ovary cells (CHO cells) that are used for recombinant antibody production are based on the Chinese hamster cells, but can be cultured in vitro. Hence, no hamsters are used in the actual process.

Not only is the use of cells that were cultured in vitro important for animal rights, it also generates antibodies with a much higher specificity than those achieved through animal immunization methods.

Read more: In vitro antibody production

evitria AG offers recombinant antibody production services to customers worldwide. Focus is on the production of recombinant antibodies using mammalian cell expression systems. CHO cells antibody production offers several advantages over bacterial and yeast systems. Mammalian cells are capable of performing complex post-translational modifications, such as glycosylation, that are necessary for the production of functional antibodies. Furthermore, our CHO cell expression platform allows producing high volumes with no limitation in quality.

Our expertise in the production of recombinant antibodies makes us a valuable partner for companies and researchers in the biotechnology industry who require high-quality antibodies for various applications.

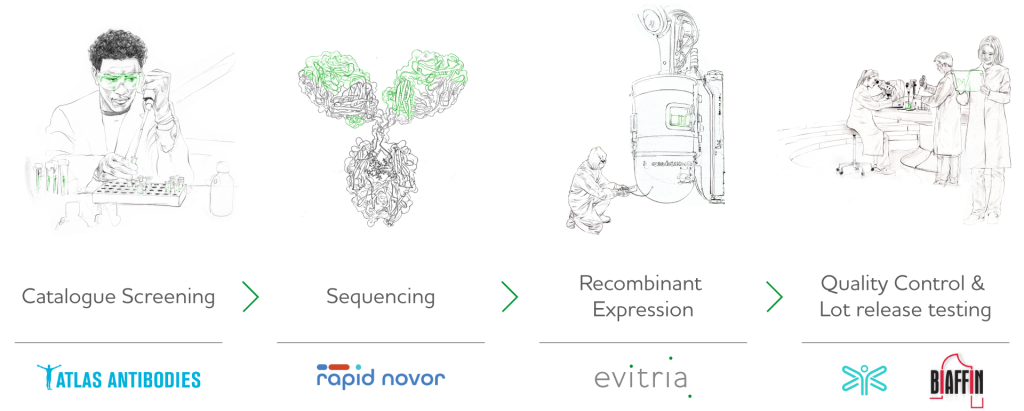

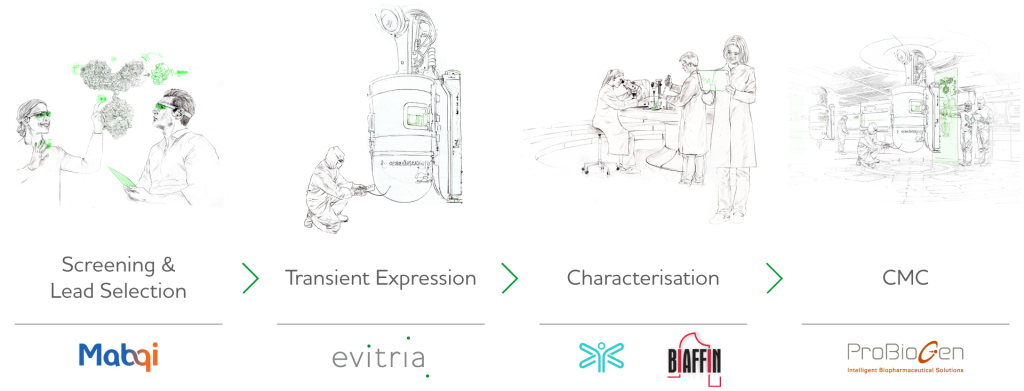

At evitria, our main focus is on transient antibody expression in CHO. Nonetheless, we collaborate with a group of reliable partners who possess specialized expertise. No matter the nature of your project, evitria can provide you with the necessary support.

Find two of our workflows with trusted partners here:

Recombinant antibody production is a powerful tool for generating high-quality antibodies for various applications, including research, diagnosis, and therapy. It involves the use of gene expression systems, such as bacterial or mammalian expression systems, to produce recombinant proteins that can then be purified and used as antibodies.

The use of recombinant DNA technology has greatly improved the efficiency and scalability of antibody production, while antibody engineering and optimization has enabled the generation of antibodies with improved properties, such as specificity, affinity, and compatibility with the human immunesystem, making them beneficial for therapeutic antibody production.

Recombinant antibody production is a rapidly evolving field with enormous potential for research, diagnosis, and therapy. By harnessing the power of genetic engineering and antibody optimization, it is possible to create highly specific and effective antibodies that can be used to address a wide range of biomedical challenges.

We produce recombinant antibodies using a CHO-based expression system. Our expertise in protein expression allows for rapid project timelines and successful production of even difficult-to-express antibodies. The expected project timelines are typically 5 weeks for new antibodies and 1-2 weeks for reproductions. More about our recombinant antibody expression serivce.

Recombinant antibodies are produced by using genetic engineering techniques to introduce antibody genes into host cells, such as bacteria or mammalian cells. The host cells then produce the recombinant antibodies, which can be purified and used for various applications, including research, diagnosis, and therapy.

Recombinant DNA technology means the different steps that are needed to produce recombinant antibodies. At first, antibody genes have to be recovered from source cells to create a vector. Next, this vector can be introduced into a host cell which is then led to express the desired antibody.

Polyclonal antibodies are typically produced by immunizing an animal, such as a rabbit or goat, with an antigen, which triggers the animal’s immune system to produce a range of antibodies. The antibodies are then harvested from the animal’s serum and purified for use in various applications.

Monoclonal antibodies (mAbs) are produced by the fusion of B cells, which produce specific antibodies, with cancerous myeloma cells, which can grow indefinitely in culture. The resulting hybrid cells, called hybridomas, can produce large quantities of identical antibodies. The hybridomas are then screened to identify those that produce the desired antibody. The selected hybridoma cells are then grown in culture to produce the mAbs, which can be purified and used for various applications such as research, diagnosis, and therapy. Read more in the article about monoclonal antibody production.

Antibody phage display technology is a method to select antibodies in various isotypes (e.g., IgG1) using bacteriophages in order to identify high potency antibodies.

A single-chain variable fragment (scFv) is a compact antibody format consisting of fused variable regions (VH and VL) connected by a linker. It retains antigen-binding specificity while being smaller and more easily engineered than full-length antibodies.