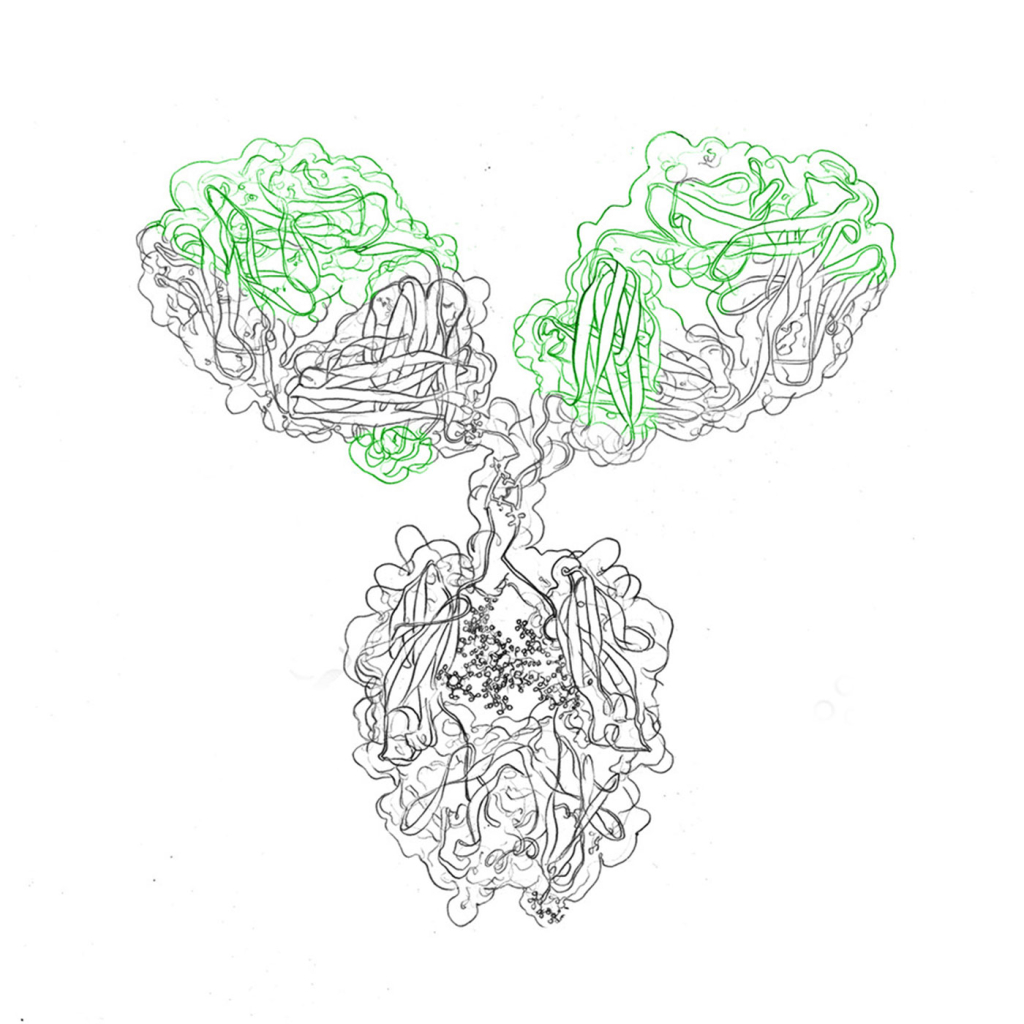

The purification of recombinant antibodies is an indispensable step in the overall protein production, thus also essential for various aspects in therapy, diagnostics and research. Nevertheless, different antibody formats – be it full-length abs or antibody fragments – are valued for their distinctive antigen-binding properties respectively the ability to bind to one specific epitope, which is a great advantage over polyclonal antibodies and opens a wide range of different applications.

After their recombinant expression, recombinant antibodies are not immediately ready to use. Instead, they need to go further processing steps of recombinant antibody production – one of them being the purification of recombinant antibodies.

The definition of recombinant antibody purification refers to the process of isolating and separating a specific recombinant antibody from a complex mixture of other proteins, cellular debris, and impurities.

The goal of purification is to obtain a high yield of pure recombinant antibody, suitable for research, diagnostic, or therapeutic purposes.

Subscribe to our Newsletter

Get all the latest updates, and learn about our advancements in antibody production.

Subscribe now

The common procedure for purifying antibodies include an initial centrifugation and filtration process, cell lysis, followed by the use of multiple chromatography techniques. The purification process of proteins is complex due to the diversity and distinct properties of proteins, and there is no single approach in protein purification.

Typically, target proteins are first designed to be affinity tagged to facilitate the purification process, allowing target proteins to maintain their properties without interacting directly with a matrix.

When developing a purification strategy, it is crucial to keep the end goal for the purified protein in mind. A popular purification method is affinity chromatography (or affinity purification), where the unrefined sample is made to flow through a column that is packed with protein A.

The technique is widely used to separate a biomolecule from a mixture by making use of a specific macromolecular binding interaction, which is determined by the biomolecule of interest, e. g. antibody and antigen, substrate and enzyme, ligand and receptor, or nucleic acid and protein.

Despite significant progress, physicochemical-based chromatographic methods such as size exclusion (SEC), ion exchange (IEX), and hydrophobic interaction (HIC) are often required in addition to affinity tags.

Another method of protein tagging involves engineering an antigen peptide tag onto it, which can then be purified on a column or via incubation. The purified tagged proteins can be easily separated from other proteins and released into the elution buffer. To remove tags, a protease cleavage site can be added between the tag and the protein.

To monitor the progress and results of each purification step, SDS-PAGE can be used during the purification process. Despite the availability of alternative technologies, coomassie staining remains one of the most commonly used methods for visualizing protein bands on gels.

To create appropriate conditions for recombinant antibody purification, it is recommended to use a French press with a continuous-fill cell for regular small to medium-scale tasks or a Manton-Gaulin-APV homogenizer for large-scale work.

For proper handling of cells and cell lysate, it is necessary to use an ultrasonic homogenizer. Chromatography is typically conducted at a temperature of 4°C. The fundamental elements of a chromatography system comprise of a column, column matrix, pumps, a gradient generator, a detection system such as UV/visible, and a fraction collector.

Recombinant antibody purification plays a crucial role in the production of antibodies, including full-length IgG1 antibodies, heavy-chain and single-chain antibodies (scFv), and antibody fragments like Fab. The initial recombinant antibody expression typically involves the use of bacterial expression systems (e.g. Escherichia coli) or mammalian cells such as HEK293 cells or CHO cells.

During the expression phase, codon optimization is often employed to enhance protein production, and characterization assays are conducted to validate the functionality and specificity of the immunoglobulins (IgG antibodies). The choice of host cells, whether bacterial or mammalian cells, depends on the desired glycosylation patterns and protein folding requirements.

In certain cases, antibody production may involve hybridoma technology or phage display methodologies, leading to the generation of mAbs (monoclonal antibodies). Regardless of the production approach, it is essential to monitor protein concentration and remove impurities, including endotoxin, to ensure the final product’s quality.

The recombinant antibody purification process often includes the use of affinity tags, such as the Fc domain or antigen peptide tags, to facilitate efficient purification. By utilizing these tags, the target antibodies can be isolated from the complex mixture of cellular components and reagents.

Recombinant protein expression and purification comes with several challenges in practice. The accumulation of the product within the cell can trigger stress responses that impede cell growth. The buildup of insoluble and biologically inactive aggregates (inclusion bodies) reduces the production yield, especially when attempting to obtain high molecular weight, multi-domain, or membrane proteins.

Additionally, recombinant protein expression requires meticulous planning and process optimization to determine the appropriate host, culture conditions, duration, and purification strategy.1

Antibody expression service providers like evitria are equipped with the know-how and necessary capacities for recombinant antibody expression and purification. The company is fully focused on the expression of recombinant antibodies in CHO cell cultures, offering services for industrial applications, small-scale usage, and discovery research. This also includes the use of advanced protein purification methods, such as

Additionally, by using CHO cells, evitria’s recombinant antibody expression platform harnesses their benefits without relying on laboratory animals and their immunization – making the company’s products free from any animal contaminants – while allowing faster timelines and greater yield than traditional methods.

What does the production process of recombinant antibodies look like?

Recombinant antibodies are synthesized in vitro by incorporating the heavy and light chains of the antibody into an expression vector. Following expression, they are usually isolated from periplasmic fractions or the culture supernatant.

What are recombinant proteins?

Recombinant proteins are often considered as high-tech products in biotechnology and require know-how across many disciplines such as cell biology, biochemistry, and molecular biology. They can be defined as long chains of condensed amino acids, produced by host cells.

These were reprogrammed to transcribe recombinant DNA sequences, which is the template for messenger RNA. Recombinant proteins can be designed to possess unique properties, which are not found in natural proteins. This includes synthetic enzyme for drug discovery, recombinant monoclonal antibodies, and therapeutic fusion proteins.

The solubility of recombinant proteins determines their quality; however, even a soluble protein can be limited in its ability to exhibit functional activity as it may contain non-functional, misfolded, or soluble aggregates.2

How are recombinant proteins produced?

What is SDS-PAGE?

SDS-PAGE stands for sodium dodecyl sulfate – polyacrylamide gel electrophoresis and is often used for separating proteins with molecular masses ranging from 5 to 250 kDa. By using a combination of polyacrylamide gel and sodium dodecyl sulfate (SDS), the influence of structure and charge can be eliminated, allowing proteins to be separated based solely on their molecular weight differences.