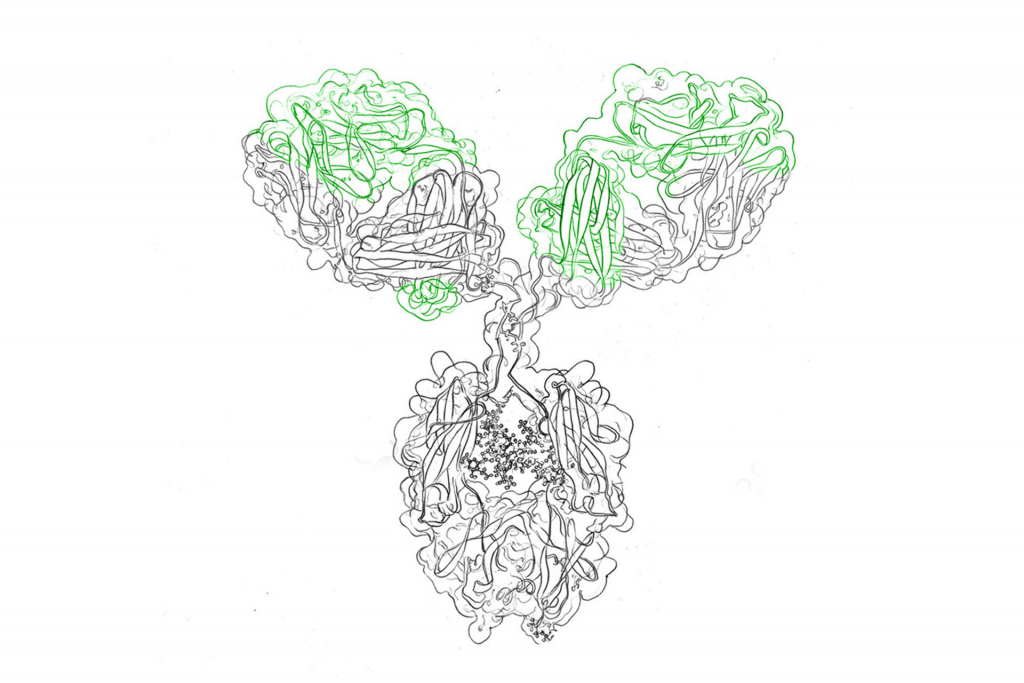

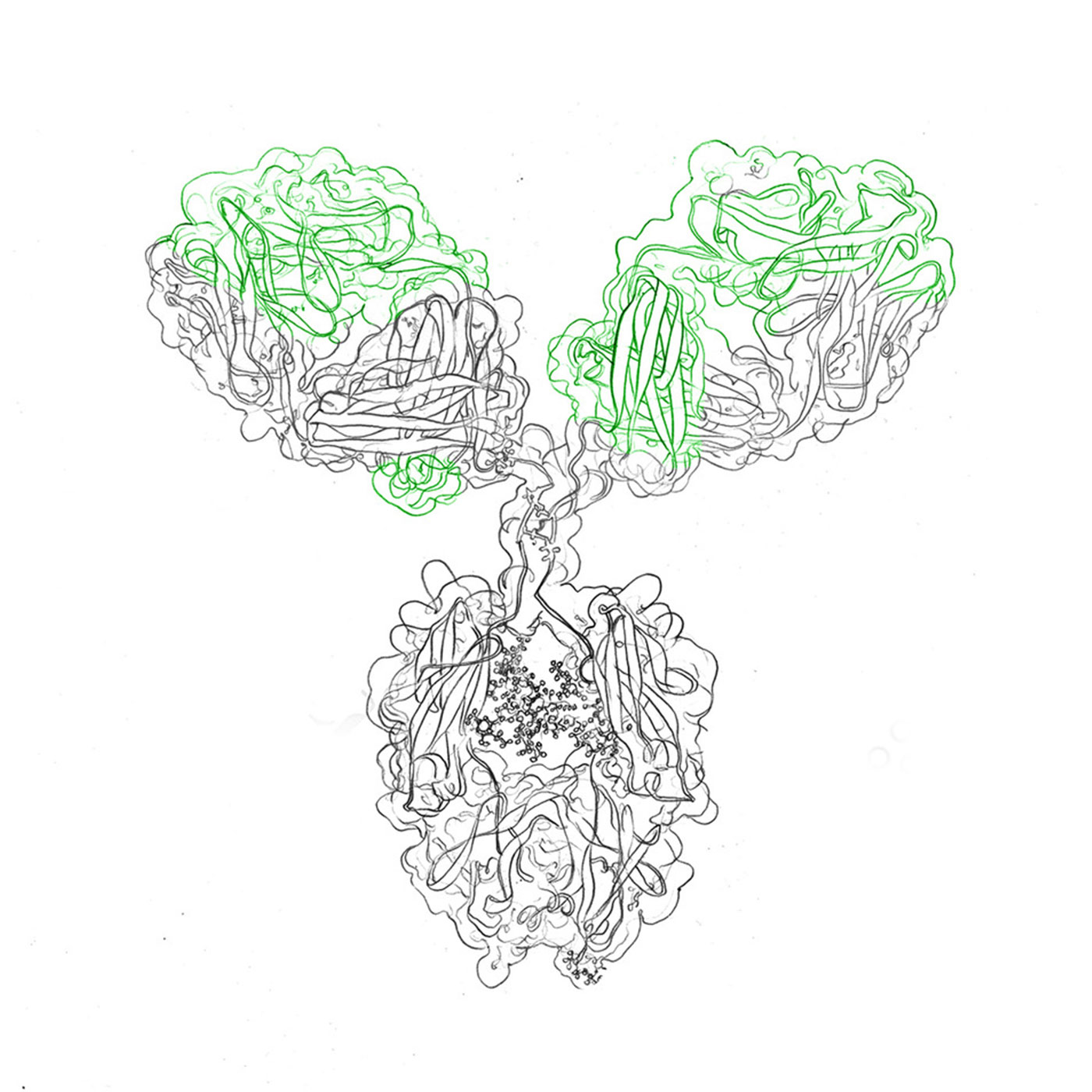

Recombinant monoclonal antibody production

We are a leading service provider for recombinant antibody production. Get in contact!

The different steps in antibody production shape a key process for several scientific fields, including medicine and research. They need to be carried out according to distinctive protocols in order to obtain high quality products, such as monoclonal or recombinant antibodies.

Covering both the production process itself and challenges related to it, this article will provide a detailed description of different steps in antibody production.

Antibody production involves a number of steps that require great diligence, a high level of expertise and costly devices. This is why many pharmaceutical companies and research groups frequently outsource antibody production to CROs, saving both costs and resources.

In general, the antibody production process is composed of the following steps.

Subscribe to our Newsletter

Get all the latest updates, and learn about our advancements in antibody production.

Subscribe now

Before antibody production can begin, the targeted antigen needs to be purified. This step ensures that the antigen is free from contaminants and maximizes its effectiveness in stimulating an immune response. Techniques such as affinity chromatography are commonly used to achieve antigen purification.

To enhance the immune response, the purified antigen is combined with an immunogenic carrier protein. The selection of an appropriate carrier protein is crucial, considering factors such as immunogenicity, stability, and compatibility with downstream applications.

The next step involves the combination of the purified antigen and the selected carrier protein. This process forms an antigen-carrier protein complex, which will serve as the basis for the subsequent immunization steps. The combination ensures that the immune system recognizes the antigen as a foreign substance, triggering an immune response.

The antigen-carrier protein complex, also known as an immunogen, is formulated to stimulate a strong immune response. The immunogen is designed to present the antigen in a way that effectively activates the immune system, leading to the production of antibodies with high specificity towards the target.

In order to generate a robust antibody response, the immunogen is used to immunize animals. Commonly used animal models include mice, rabbits, and goats. The animals’ immune systems recognize the immunogen as foreign and produce a diverse pool of antibodies in response.

To obtain a continuous and renewable source of specific antibodies, the hybridoma method is employed. This method involves fusing antibody-producing cells (derived from immunized animals) with immortalized cells, resulting in the creation of hybridoma cells. These hybridoma cells have the ability to continuously produce antibodies with the same specificity as the original cells.

With the aim to ensure optimal growth and antibody production, cytokines are introduced to the hybridoma cells. Cytokines are signaling molecules that regulate cell growth, division, and differentiation. By providing the necessary growth factors, cytokines help maintain the viability and productivity of the hybridoma cells.

The phage display method is used to identify mature antibodies with high affinity and specificity. This technique involves exposing the hybridoma cells to a dilution series, allowing for the selection and amplification of antibodies with desired binding properties. Phage display enables the detection of antibody maturation and the identification of antibodies with optimal characteristics, before further steps are taken to finish and harvest the expressed antibodies.

While antibody production is a vital process, it comes with its share of challenges. Some challenges include optimizing production yields, ensuring batch-to-batch consistency, and maintaining product quality.

Additionally, ethical concerns arise regarding the use of animals in the immunization process. Striking a balance between scientific advancements and animal welfare is an ongoing consideration in antibody production, as well as finding alternative to involving live animals in antibody production, e.g. by the use of HEK or CHO cells.

In antibody production, selecting the right expression system is crucial. Among the options available, Chinese Hamster Ovary cells (CHO cells) have become a frequent choice. Here’s why:

We are a leading service provider for recombinant antibody production. Get in contact!

At evitria, we are focused on the production of recombinant monoclonal antibodies for various applications – be it for the use in research or, at large scale, in the pharmaceutical industry.

To meet the high requirements of our partners in terms of quality, production time, and regulatory as well as ethical considerations, we rely on CHO cells for our recombinant antibody production services. Combined with our expert knowledge in recombinant protein expression, they allow us to provide partners worldwide with high quality antibody products.