Antibody production with evitira

We offer recombinant antibody production in CHO cell lines. Get in contact!

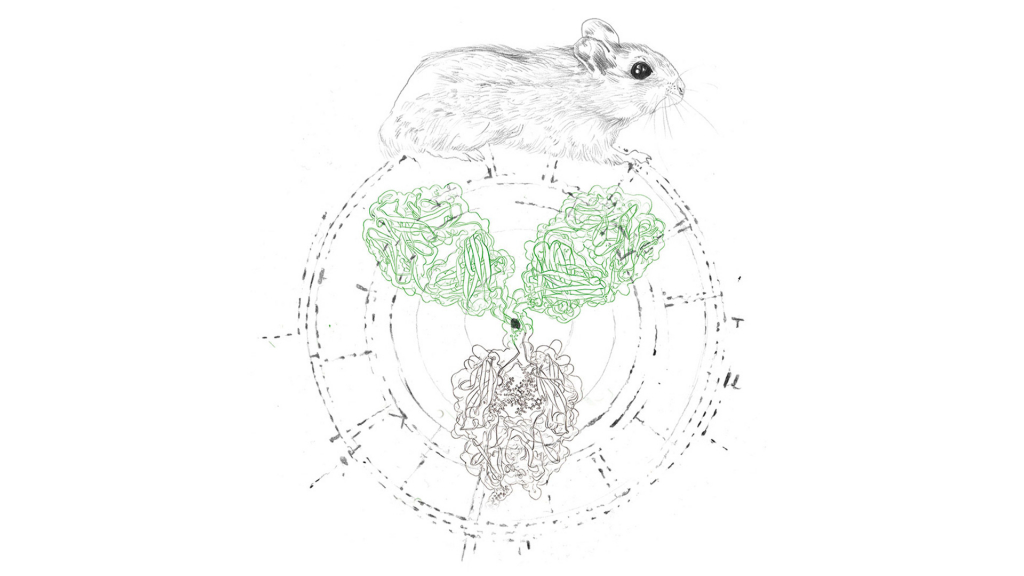

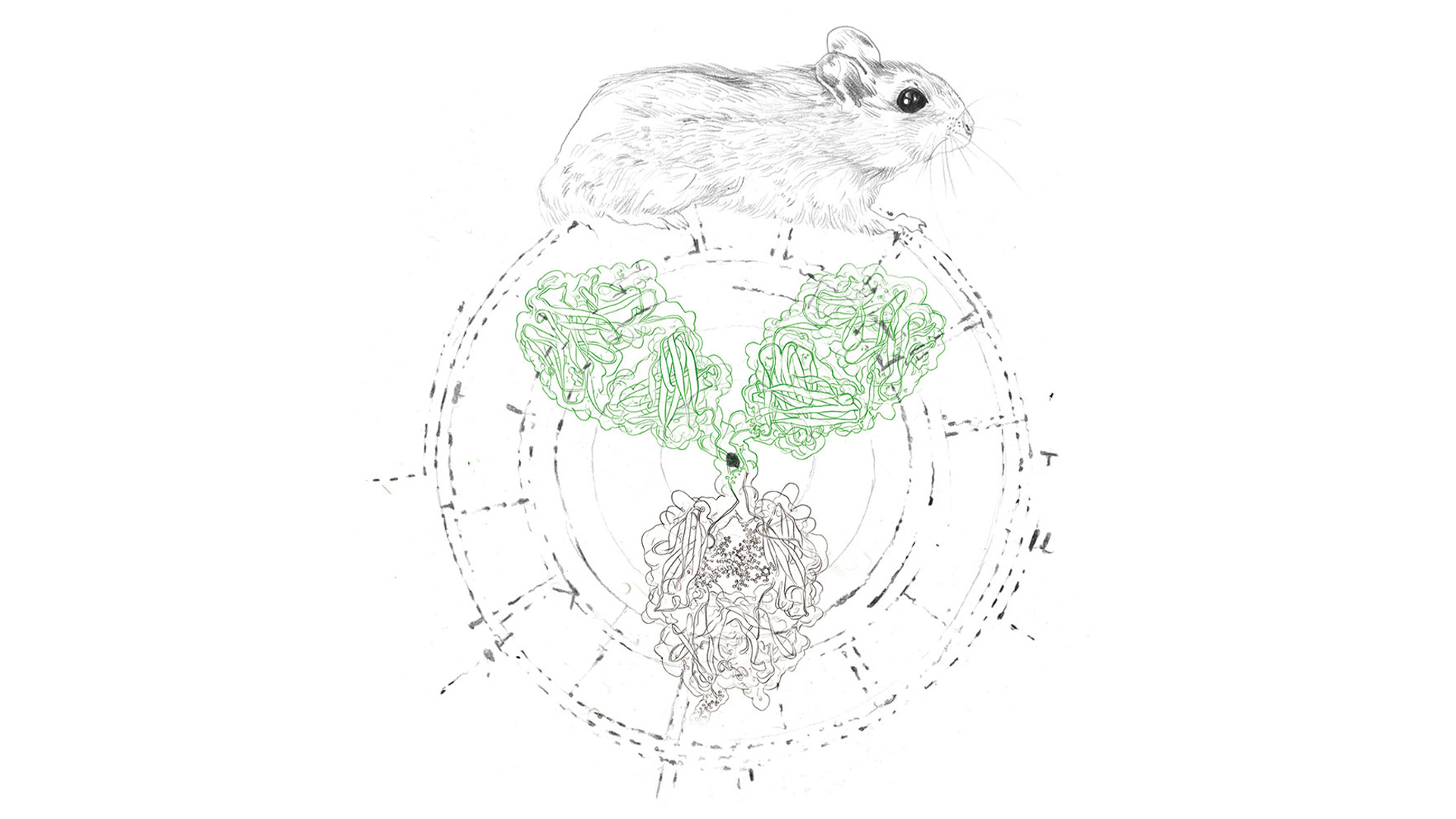

CHO cells antibody production has revolutionized the biopharmaceutical sector. Through years of research on optimizing the process of therapeutic antibody production, Chinese hamster ovary cells have proven themselves to be especially valuable to biotherapeutics production methods.

The many advantages of Chinese hamster ovary cells propelled them to become the most used mammalian cell culture in pharmaceutical biotechnology today.

In this article we will examine their benefits and provide information on recombinant antibody production methods, potential downsides to the usage of CHO cells as well as a glimpse into the future of CHO cells in biotechnology.

Through CHO cell antibody production, it became possible to derive therapeutic antibodies as treatments for diseases like cancer, multiple sclerosis, asthma, HIV or neuroblastoma. The use of CHO cells for the production of recombinant antibodies has led to a boost in the production process of recombinant protein therapeutics. Due to their large success, manufacturers use CHO cells in the different steps of recombinant antibody production: Transfection, recombinant protein production, purification and antibody expression.

Subscribe to our Newsletter

Get all the latest updates, and learn about our advancements in antibody production.

Subscribe now

To use CHO cells to express recombinant proteins in bioprocessing was a huge step forward compared to achievements with any other animal cell. This includes human cell lines which run at a greater risk for viral contamination and subsequent transmission in monoclonal antibody mAb production.

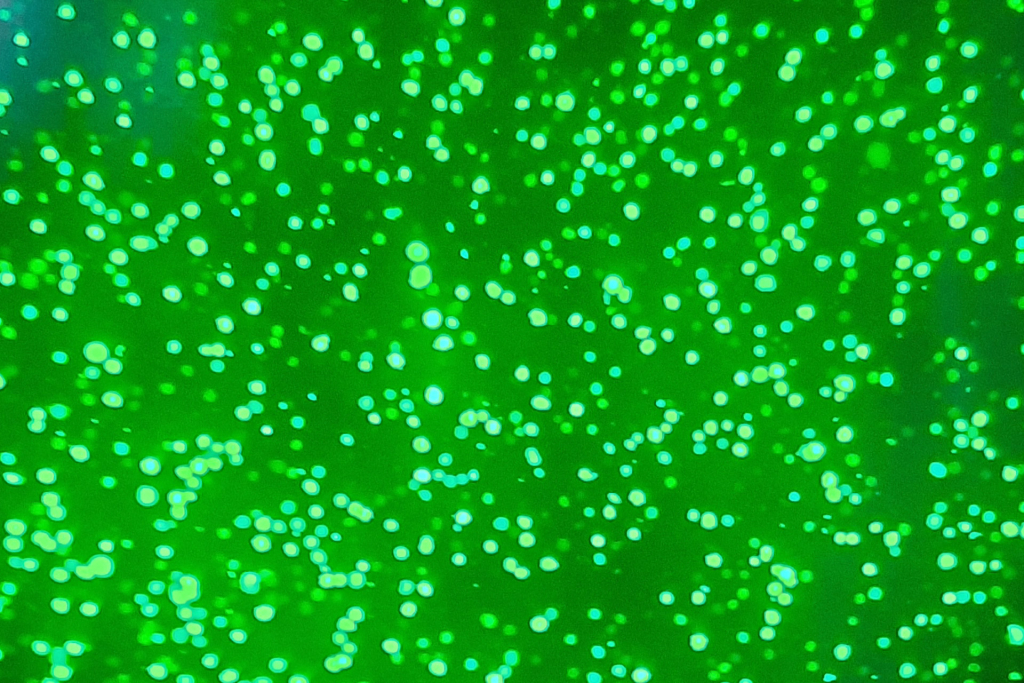

In comparison, CHO cells have shown to be very stable in antibody expression with almost no contamination risks. Moreover, compared to other mammalian cells used in bioprocessing, CHO cells are able to produce a very high level of recombinant protein.

Over the years, the production of monoclonal antibodies has shifted from a reliance on hybridoma cell lines to recombinant technologies. The cloning of antibody-encoded genes into different expression hosts solved the problem of frequently lost antibody encoding genes during long-term cultivation and allowed for large-scale therapeutic production optimization.

The most common cell cultures used in antibody production today are mammalian cells as they produce glycoproteins with established therapeutic efficiency. Moreover, transfected mammalian cell lines secrete the proteins to the medium which allows for high production yields and lower purification costs.

The most used host cell lines in the production of monoclonal antibodies today are CHO cells, HEK (human embryonic kidney) cells and mouse myeloma host cell lines. However, CHO cell culture and HEK cells remain the most popular and efficient in industrial production of therapeutic recombinant proteins.

Through genetic manipulation by mutagenesis, different CHO daughter cells with improved qualities have been established. Among those variants are CHO-K1, CHO-S, CHO-DXB11 and CHO-DG44. With CHO cells, titer of produced antibodies can reach 4.35 grams per liter with a high cell density achievement.

The use of CHO cells in antibody expression is not popular without a reason. There are many, to be exact.

The ability to produce posttranslational modifications through glycosylation sets CHO cells apart from bacterial cells and makes them the cell culture of choice in antibody production. However, in the characterization of CHO cells it also has to be mentioned that their metabolic rate is lower than that of hybridoma cells which leads to lower cell growth and antibody expression in comparison.

Yet, protein expression in CHO cells is much easier to control than in hybridoma cells. This potential has been recognized in bioengineering. Consequently, through cell engineering and research on the impact of glutamine on dynamic metabolite flux, the apparent flaw of low efficiency in CHO cells has been optimized. It is now possible to create IgG in high production yields.

CHO cells are easy to culture, allow high specific productivity with an expression system similar to human recombinant protein production and are at the same time prone to a low risk of cell death or apoptosis due to prolonged viability.

Nearly 70 % of therapeutic proteins are produced by CHO cells1, and serum-free medium is necessary for them to produce recombinant protein therapeutics.

CHO cell culture media is recognized for its product quality and FDA approved. It is used in over 50 biotherapeutics in the USA and the EU.

After exploring the many benefits of the use of CHO cells in antibody production, we will now explain what the process of the production of antibodies in CHO cells actually looks like.

At the beginning of the CHO cell antibody production process, it is necessary to start with cell line generation and selection. Media optimization is processed in small scale systems – 96-well plates –, shaker flasks and a bench-scale bioreactor that allows high screening purposes throughout the whole procedure of cell line development.

As soon as the genome is planted into the cell, supplement and nutrients are needed as an inhibitor to promote cell growth and enhance the concentration of enzyme. Perfusion culture helps to keep the viable cell concentration and the volume within the bioreactor stable.

Through cytotechnology it is possible to detect contamination and anomalies in cell culture processes from the beginning. Hence, the quality of each batch is guaranteed.

In the following, the necessary steps in the procedure of antibody production in CHO cells will be explained:

It can be said that the downsides to using CHO cells for antibody production are rare. More so, they keep on disappearing due to new developments and achievements in research on antibody production in regard to production yields and purification costs.

A main concern for many is the use of living animals in the process. However, although the original CHO cells have been extracted from Chinese hamsters, it is now possible to recreate them in vitro without the involvement of a living creature in the process.

We offer recombinant antibody production in CHO cell lines. Get in contact!

The future of CHO cell antibody production development promises to stay exciting and holds many surprises in the future. As one of the weak points of CHO cell antibody production might be the production of complex antigens in high rates, new technologies emerge to tackle this problem by enhancing cell durability.

While an increasing number of new biotherapeutics like viral antigens, vaccines, bi- and tri-specific antibodies have been able to derive from CHO cell cultures, we are excited to see what the future holds for CHO cell antibody production. CHO cells have come a long way from the first production of insulin to over 50 biotherapeutics in the USA and EU today. Due to the many benefits examined in this article, we at evitria are convinced that new, revolutionary developments lie ahead of us.

At evitria, we provide recombinant antibody expression services for both commercial and smaller-scale applications, with a particular focus on in vitro CHO cell culture-based production. Our technology leverages the advantages of CHO cells described in this article, allowing us to eliminate the need for laboratory animals and their immunization, resulting in no animal contaminants in our recombinant antibodies.

With our CHO cells antibody production service, we offer faster turnaround times and greater yields compared to conventional methods. We can also provide significant quality advantages over traditional monoclonal antibody production, even with these faster and higher yields.

Our expertise includes the production of various recombinant antibodies in CHO cells, including chimeric, bispecific, Fc-optimized and fusion antibodies, afucosylated antibodies, and Fc-silenced antibodies. Using CHO cells for recombinant antibody production offers several advantages, including high expression levels, stability, and the ability to perform glyco-engineering and other modifications. Additionally, we offer a wide array of purification methods – from affinity chromatography using protein A and other resins to advanced protein polishing techniques. We leverage these benefits to provide top-notch antibody production services for research, therapeutic, and diagnostic purposes.

CHO (Chinese hamster ovary) cells are a commonly used mammalian cell line in biotechnology for the production of therapeutic proteins, such as antibodies, hormones, and enzymes. These cells are chosen for their ability to produce complex proteins with post-translational modifications, making them suitable for use in biopharmaceutical manufacturing.

There are several types of cells that can be used for antibody production, but the most common are mammalian cells such as Chinese Hamster Ovary (CHO) cells, HEK293 cells, and NS0 cells. CHO cells are the most widely used for the production of recombinant monoclonal antibodies due to their ability to perform post-translational modifications on the antibody molecules, resulting in improved antibody stability and efficacy.

CHO cells are often used to produce antibodies in the biotechnology industry due to their ability to properly fold and modify complex proteins, like antibodies. They also exhibit stable growth and have the ability to produce high yields of recombinant proteins, making them an attractive choice for biomanufacturing.

CHO cells are beneficial for recombinant antibody expression because they have the ability to perform post-translational modifications similar to human cells, resulting in properly folded and functional antibodies. They also have high yield and scalability in bioreactor production, making them a preferred choice for industrial-scale production of recombinant antibodies.