Recombinant monoclonal antibody production

We are a leading service provider for recombinant antibody production. Get in contact!

Monoclonal antibody production is a crucial aspect of modern medicine, with applications ranging from disease diagnosis to targeted therapies. The mAb production process involves creating large quantities of identical antibodies that can recognize and bind to specific proteins or cells in the body. With the rise of biotechnology, various methods have been developed to produce monoclonal antibodies, including hybridoma technology, phage display, single b cell and recombinant technology.

This article will give an overview of the most popular and successful methods for monoclonal antibody production. From initial hybridoma production to phage display, single b cell technology and recombinant production – we will explain monoclonal antibody production step by step.

Over a hundred monoclonal antibodies (mAbs) are approved by the US FDA for human use in immunology (autoimmune diseases such as rheumatoid arthritis), infectious diseases (e.g. against SARS-COV-2 “coronavirus”), and oncology (e.g. immunotherapies, ADCC antibodies and antibody drug conjugates). With thousands of ongoing in vivo studies and clinical trials, the widespread application in diagnostics (enzyme-linked immunosorbent assay, ELISA) and general use as research reagents, the worldwide demand for mAbs is ever increasing.

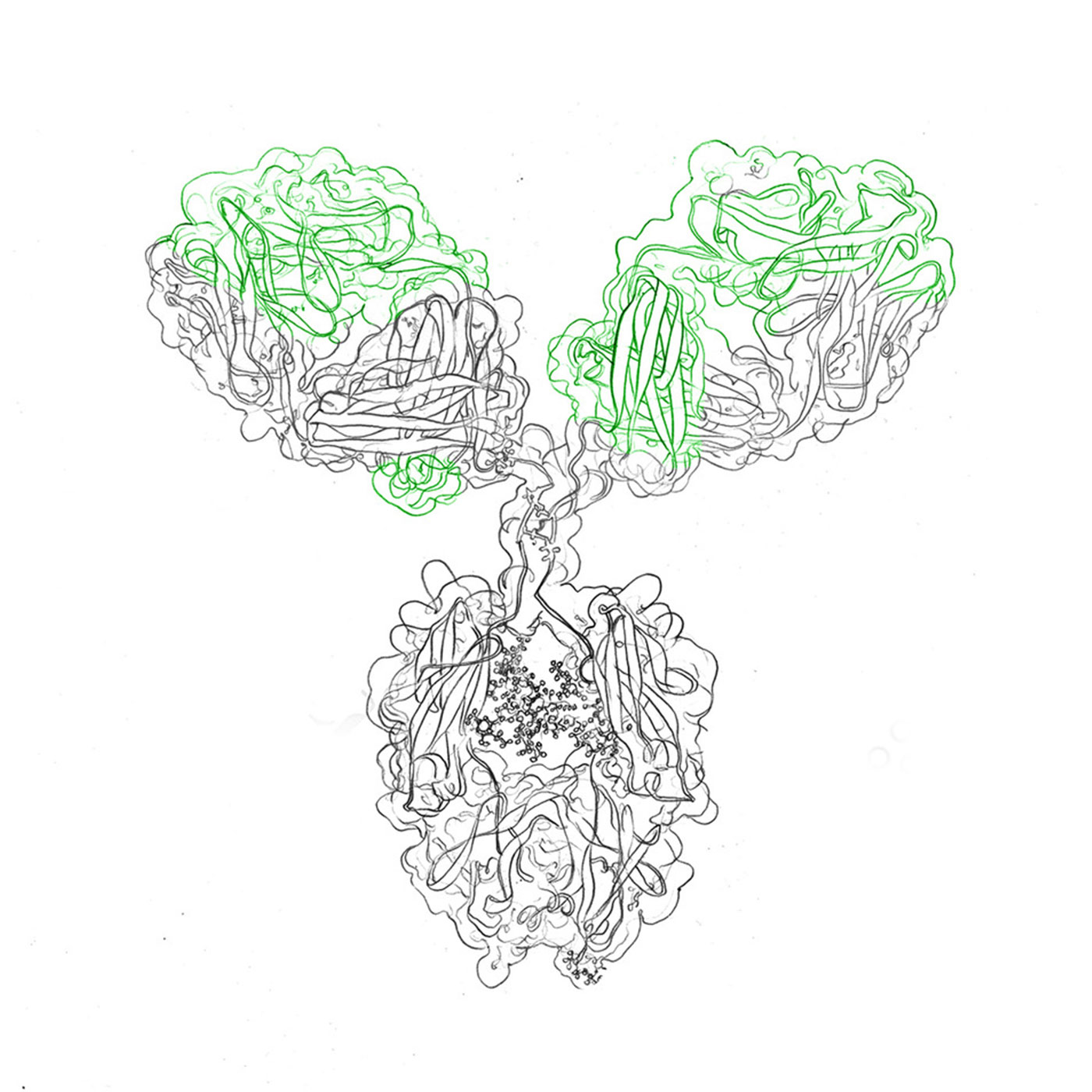

In contrast to polyclonal antibodies that target many structural regions (epitopes) of an antigen, mAbs show high specificity for one single epitope. Biologically speaking, each monoclonal antibody is secreted by one single B lymphocyte, hence the name “monoclonal”. Selectively isolating and culturing lymphocytes has been elusive until 1975, when Köhler and Milstein found a way to immortalize B cells, thus being able to generate identical copies of antibody producing cells and culturing them for extended periods of time.

Subscribe to our Newsletter

Get all the latest updates, and learn about our advancements in antibody production.

Subscribe now

Human monoclonal antibodies are biotechnological tools with very large traded volumes, thus large-scale commercial manufacturing is employed. In principle, three methods are currently used:

Each method has its advantages and disadvantages and is chosen based on the specific requirements of the desired monoclonal antibody. In the next paragraphs, we will take a closer look at the technologies. If you want to learn more about antibody production in general, read our articles: Antibody production and In vitro antibody production.

The monoclonal antibody production by hybridoma cells made monoclonal antibody treatments first feasible from the late 1970s on. After injecting an animal with the antigen of interest, spleen cells are isolated and fused with myeloma cells to combine the properties of both cell types: antigen-specific Ab-secretion and being immortal. The resulting cell lines undergo characterization assays and are validated to produce the specific antibody of interest and then either cultured by the ascites method (transplantation into animal peritoneum) or cell culture in bioreactors.1

The method relies on suitable immune responses of the injected animal to the antigen and requires humanization (chimeric antibodies) of the antibodies to reduce immunogenicity, meaning side effects due to being recognized as foreign by the patient’s immune system.

Phage display technology was developed in the early 1990s.2 Using recombinant technology, the genetic code for antibodies (mostly of the variable region Fab) is fused in vitro to genes for surface peptides of bacteriophages. After introducing these genetic blueprints into bacterial cell cultures, the next generation of phages will present the antibodies on their surface, thus physically linking the amino acid sequence of antibodies with their respective DNA (=phage library).3

This allows scientists to expose the antibody-bearing phages to immobilized antigens of interest – similar to receptors – and enrich conjugates with higher affinity. Biochemical amplification of the associated genetic material and subsequent sequencing yields bioinformatic data to inform the development of full-length human antibody constructs. The resulting construct is then introduced into suitable mammalian cells that produce the desired antibody therapies.

Monoclonal antibody production with single B cell technologies starts with blood samples from human donors. Modern methodologies are employed to screen and sort single B cells using fluorescent reagents with flow cytometry and antigens on magnetic beads to enrich promising cells.

Genetic information of single cells is extracted using reverse transcription PCR with suitable primers to focus on Ig-regions of interest. Promising genes are then cloned and expressed in mammalian cell lines to produce a first set of antibody candidates for screening and characterization of their expression properties. The hits are then introduced into mammalian cell cultures to produce fully human mAbs.

We are a leading service provider for recombinant antibody production. Get in contact!

The production of monoclonal antibodies involves several key steps, including immunization, hybridoma production, screening and cloning, and monoclonal antibody purification. Let’s take a closer look at each of these steps based on the production of monoclonal antibodies from hybridomas.

The first step in monoclonal antibody production is immunization. Immunization involves injecting an animal with the antigen of interest. The animal’s immune system will then recognize the antigen as foreign and produce an immune response. This immune response will result in the production of B cells that produce antibodies against the antigen.

After immunization, B cells are extracted from the animal’s spleen and fused with myeloma cells to create hybridoma cells. Myeloma cells are a type of cancerous B cell that can be grown indefinitely in the lab. The hybridoma cells created through fusion will have the ability to produce large amounts of antibodies.

The hybridoma cells are then screened to identify the cells that produce the desired antibody. This is done using a technique called enzyme-linked immunosorbent assay (ELISA). ELISA involves coating a plate with the antigen of interest and then adding the hybridoma cells to the plate. If a hybridoma cell produces the desired antibody, it will bind to the antigen on the plate, and the antibody can be detected using a secondary antibody.

Once the hybridoma cells that produce the desired antibody are identified, they are cloned. Cloning involves isolating a single cell and allowing it to divide and grow into a population of identical cells.

The final step in monoclonal antibody production is purification. Purification involves separating the monoclonal antibody from the other proteins and substances present in the cell culture. This is typically done using a combination of chromatography techniques. At evitria, for instance, we offer techniques like affinity chromatography using protein A and other resins, as well as specialized columns and protein polishing methods like size exclusion chromatography and ion exchange chromatography.

The production of mAbs is a complex undertaking that requires the concerted efforts of cell and molecular biologists, bioinformaticians and biotechnological engineers – and this just concerns the operative side. Additionally, management of raw material supply chains, quality control, regulatory affairs, capacity management and logistics are challenging aspects.

Critical steps in monoclonal antibody development need to be managed carefully in order to achieve high quality immunoglobulins in the desired quantity. Although monoclonal antibody production has many advantages for science, production is fraught with limitations and challenges. We will take a closer look at these in the next chapter.

Despite their numerous applications and advantages, monoclonal antibodies also have some challenges and limitations. Here are some of the major challenges and limitations associated with the production and use of monoclonal antibodies:

Despite these challenges and limitations, monoclonal antibodies continue to be valuable tools in research, diagnostics, and therapeutics. Ongoing research and development efforts are focused on addressing these challenges and expanding the potential applications of monoclonal antibodies.

Monoclonal antibodies in various isotypes (such as IgG) are produced by a variety of organizations, including academic institutions, biotechnology companies, and pharmaceutical companies. These antibodies have a wide range of applications, from diagnostics to therapeutics.

To learn more about the topic, you can read the article Manufacturers of monoclonal antibodies

Recombinant monoclonal antibody production is an alternative method for the production of monoclonal antibodies that involves the genetic engineering of antibody genes to create highly specific and functional antibodies. Unlike traditional monoclonal antibody production methods, recombinant monoclonal antibody production does not require the use of animals for antibody production, and it can produce large quantities of highly specific antibodies in a shorter time frame.

The process of recombinant antibody production involves the isolation and identification of the variable regions of the antibody genes, which are responsible for the antibody’s antigen-binding specificity. These variable regions are then inserted into expression vectors, which are used to produce large quantities of recombinant antibodies in mammalian or bacterial cell culture systems.

One of the major advantages of recombinant antibody production is the ability to engineer and modify antibodies to enhance their therapeutic properties, such as increased binding affinity, improved pharmacokinetics, and reduced immunogenicity. This is achieved through the manipulation of the antibody’s amino acid sequence, which can be modified to alter the antibody’s properties.

In addition to these advantages, recombinant antibody production can also reduce the variability associated with traditional monoclonal antibody production methods, as recombinant antibodies are produced using a standardized and controlled manufacturing process. This can lead to more consistent and reliable antibody products, which can be important for clinical applications.

Recombinant monoclonal antibody production offers a promising alternative to traditional methods of monoclonal antibody production, with the potential for increased specificity, functionality, and consistency. Ongoing research and development in this field will continue to advance the production and use of recombinant monoclonal antibodies in research, diagnostics, and therapeutics.4

evitria offers a service for the production of recombinant monoclonal antibodies using our CHO cell expression system. We provide customized solutions for the production of high-quality antibodies in large quantities. We are one of the leading recombinant antibody expression service provider supplying our customers worldwide. Our experience is based on over 20,000 purified antibodies, a mark we reached in 2022. With our expertise and experience in the field, we find customized solutions to meet your needs in custom antibody production.

Monoclonal antibodies are produced by fusing B cells from immunized animals with immortalized myeloma cells to create hybridomas. The hybridomas are then screened and selected for cells that produce the desired antibody. These cells are then expanded and cultured, and the monoclonal antibodies are purified prior to formulation for use in various applications.

Hybridoma technology is a method used to produce monoclonal antibodies. It involves fusing B cells from an immunized animal with immortalized myeloma cells, resulting in hybrid cells that can produce large quantities of a single antibody. This method allows for the production of highly specific and pure monoclonal antibodies for various biopharmaceutical applications.

There are several methods for monoclonal antibody production, including hybridoma technology, recombinant DNA technology, phage display, and single b cell technology.