In vitro antibody production is a powerful technique used in immunology research and therapeutic development. Antibodies (immunoglobulins) are proteins produced by the immune system as a reaction to foreign substances such as viruses, bacteria, and tumor cells.

When it comes to choosing in vivo or in vitro antibody production, the latter option offers several advantages over traditional in vivo methods, including the generation of custom antibodies, monoclonal antibodies (mAbs), polyclonal and recombinant antibodies with specific binding properties. These antibodies can be utilized for a wide range of applications, from basic research to clinical diagnostics and therapeutics.

In this article, we will discuss the basics of in vitro antibody generation and explore the various methods used to produce these valuable tools.

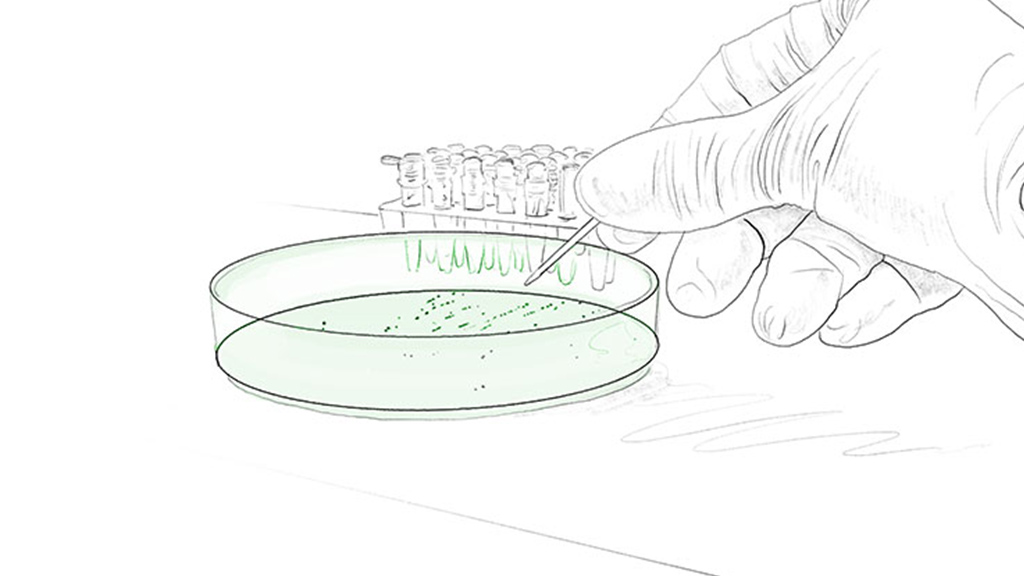

In vitro antibody production methods involve the use of hybridoma cells, mammalian cell culture, or recombinant technology to produce large quantities of monoclonal or polyclonal antibodies.

Subscribe to our Newsletter

Get all the latest updates, and learn about our advancements in antibody production.

Subscribe now

The production of monoclonal antibodies in hybridoma cells includes a set number of steps:

Mammalian cell culture can be used as an alternative expression systems of hybridoma cells. By choosing Chinese Hamster Ovarian cells (CHO cells), the use of lab animals can be avoided, as the original cell line has been harvested decades ago and cultured since then.

The process of in vitro antibody production in mammalian cells includes steps like:

In contrast to monoclonal antibodies, pAbs are by definition more heterologous and usually stem from animals, thus relying on in vivo antibody production. The process of polyclonal antibody production consists of the following steps:

However, in vitro antibody production methods offer a more controlled and ethical alternative to antibody production in animals. The use of serum-free media and mycoplasma-free reagents ensures the production of high-quality antibodies suitable for research and therapeutic applications. The selection of appropriate production methods and the validation and characterization of the resulting antibodies are crucial to ensure the production of reliable and specific antibodies.

In vitro antibody production methods have revolutionized various fields, offering diverse applications in research, diagnostics, and therapeutic development.

In the field of research and development, in vitro antibody production serves several critical purposes. Firstly, these antibodies find wide application in antibody-based assays, such as enzyme-linked immunosorbent assays (ELISA). They enable the detection and quantification of specific antigens, playing a pivotal role in various research domains, including immunology, microbiology, and cancer biology.

Secondly, in vitro-generated antibodies are invaluable for functional studies of proteins. Through their selective binding to target proteins, these antibodies aid in unraveling their roles in cellular processes, signal transduction, and disease mechanisms.

Lastly, in vitro antibody production facilitates target validation and drug discovery. Researchers can generate monoclonal antibodies (mAbs) against specific antigens to assess their potential as drug targets and expedite the development of novel therapies. The versatility and utility of in vitro-produced antibodies make them indispensable tools in advancing scientific understanding and therapeutic innovation.

In vitro antibody production has significant applications in diagnostics, playing a crucial role in disease detection and monitoring. Monoclonal antibodies generated through in vitro methods find extensive use in clinical diagnostics. By specifically targeting and binding to antigens or antibodies present in patient samples, these in vitro-produced antibodies enable reliable and precise disease detection.

Moreover, in vitro-generated antibodies contribute to biomarker detection. They are utilized to identify and measure specific biomarkers associated with various diseases. This capability aids in early diagnosis, prognosis, and monitoring of treatment response, allowing healthcare professionals to make informed decisions regarding patient management.

The versatility and specificity of in vitro-produced antibodies make them invaluable tools in diagnostic applications, facilitating timely and accurate disease identification and monitoring for improved patient care.

In vitro antibody production methods have revolutionized therapeutic applications, particularly in the development of monoclonal antibody (mAb) therapies. Monoclonal antibodies, such as immunoglobulin G (IgG), generated through in vitro methods, exhibit remarkable specificity in targeting antigens on diseased cells or pathogens. This targeted approach facilitates immune response and enables precise and effective therapy.

Monoclonal antibodies have demonstrated success in treating diverse conditions, including cancer, autoimmune diseases, and infectious diseases.

Furthermore, in vitro-produced antibodies can be engineered to create antibody-drug conjugates, allowing the targeted delivery of drugs to specific cells. This strategy enhances therapeutic efficacy while minimizing side effects associated with conventional systemic drug administration.

In addition, in vitro methods enable the production of bispecific and multispecific antibodies. These innovative antibodies possess dual or multiple specificities, enabling simultaneous targeting of different antigens or cells. Such advancements hold tremendous promise for enhancing therapeutic applications and expanding treatment options.

The versatility and impact of in vitro antibody production methods have significantly contributed to personalized medicine and the advancement of disease treatment, propelling breakthroughs in immunology and biomedical research.

In vitro antibody generation methods offer significant advantages over traditional in vivo production approaches. However, it is important to consider both the benefits and limitations of these methods to make informed decisions regarding antibody production strategies.

Pros of in vitro antibody generation include:

Some of the cons of in vitro antibody generation are:

Understanding the pros and cons of in vitro antibody generation is crucial for researchers and manufacturers when selecting the most suitable production method. Optimization of production protocols and continued advancements in in vitro techniques can address some of the limitations and further enhance the benefits of in vitro antibody generation.

Read more: Antibody production in bacteria | In vivo antibodies

In vitro antibody production presents challenges that need to be addressed for successful outcomes. Ensuring antibody stability and reducing immunogenicity are key considerations. Scalability of manufacturing processes is crucial for meeting demand, while optimizing cell culture conditions and media helps enhance antibody production.

Compliance with regulatory guidelines and selecting appropriate production methods are important considerations. Skilled expertise and specialized equipment are required, such a tissue flasks or roller bottles. This is why outsourcing antibody production is frequently chosen, as contract research organizations can offer services that help production antibodies in an efficient and safe manner.

We at evitria offer unique services in recombinant antibody production, relying on CHO cells as our preferred expression systems. This is how we can provide partners with high-quality recombinant antibodies in lab and large scale.