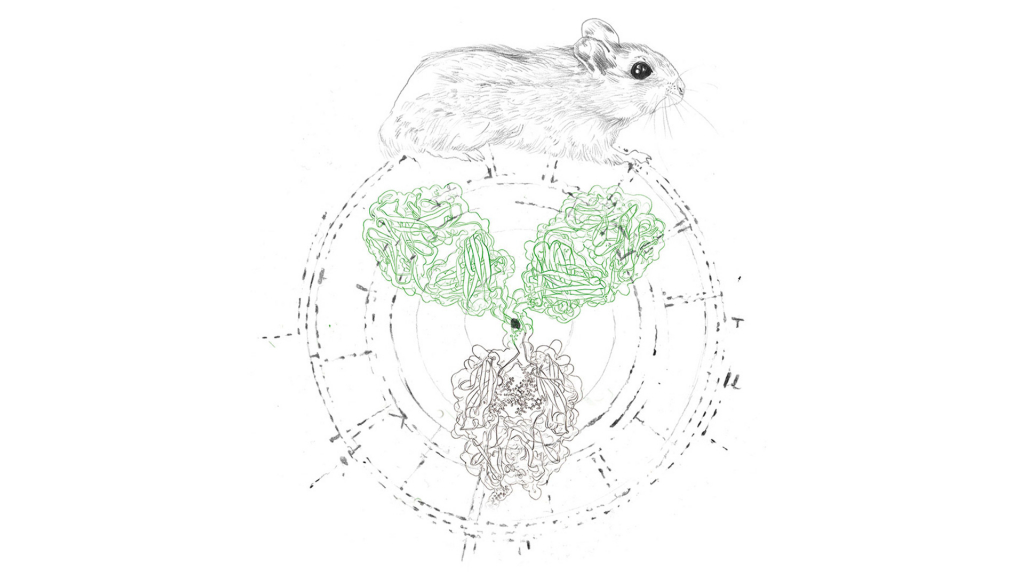

Antibody production historically relied on animals (in vivo) for polyclonal antibodies, but with the growing demand of monoclonal antibodies, recombinant antibodies and hybridoma technologies became the predominant ways antibodies are produced.

In this article, we discuss which one is better – in vivo vs. in vitro antibody production? The issue is multi-layered and strongly discussed by proponents of both sides. Historically, both approaches have had their merit, but advances in molecular biology methodology gave in vitro antibody production an edge.

First off, before discussing the cons and pros of each approach, let’s clear up the terminology we are going to use. Both terms originate from Latin, “in vivo” meaning “in an alive entity”, while “in vitro” denotes something that is kept “in glass”. Although they are used in the context of assays conducted in animals or cells, for the purposes of this article we are using these terms in the context of antibody production.

In vitro methods have become largely popular because they offer the ability to test target engagement and toxicological and immunological implications of drugs without the use of animals in drug discovery and development.

Subscribe to our Newsletter

Get all the latest updates, and learn about our advancements in antibody production.

Subscribe now

Antibodies are large and highly complex biomolecules and historically, the use of animals used to be the primary way to produce polyclonal antibodies by challenging the animal with an antigen.

With the development of hybridomas and the mouse ascites method, the immunization and subsequent sacrifice of laboratory animals to obtain antibodies became mostly obsolete, but those methods still rely heavily on animals.

With the advent of molecular biology methodology, mammalian cell lines and recombinant techniques, the use of animals ceased to be a necessity for antibody production.

Read more in the article: Monoclonal antibody production

In vivo antibody production commences with the injection of the antigen into an animal. Its immune system then responds with B-lymphocytes that mature to plasma cells that produce polyclonal antibodies against the injected antigen. This used to be historically how antibodies were produced.

With more technological advances, spleen cells were harvested from the animal and fused with myeloma cells (a type of cancer cells) to form hybridoma cells. These cells were then expanded via in vitro cell culture or injected into animals’ abdominal cavities (ascites method). The latter requires extensive animal facilities, is therefore time-consuming and raises ethical issues, but generates high amounts of antibodies. Other major downsides are the risk of contamination and requirement for antibody validation (hybridoma cells may undergo spontaneous mutations).

Read more: Antibody production in animals | In vivo antibodies

In vitro antibody production methods can be applied in ways to practically avoid the use of animals. These methods start at the level of genetic information and allow the development and engineering of full antibodies, antibody fragments, bispecific antibodies and offer the use of genetic libraries to access antibody characteristics of various hosts (human, mouse, alpaca, etc.).

Modern display methodologies like phage display and yeast display, in which the antibodies are presented at the surface of the phage or yeast, facilitate directed evolution techniques to develop genetic codes for very specific high affinity antibodies without animals. Ribosome display even circumvents the need to culture bacterial or yeast cells. These in vitro methods allow the creation of antibodies against highly toxic molecules.

Read more: Antibody production in bacteria

The optimized genes are then introduced into mammalian cells such as Chinese hamster ovary cells to produce the desired antibodies in outstanding yields and qualities. Strictly speaking, such mammalian cell lines were derived from an animal source, but ultimately originated from one specimen and are since propagated by cell division.

Whether preference should be given to in vivo or in vitro antibody production depends on the constraints and bottlenecks of the desired application or the specific project and is at the customer’s discretion:

in vivo production:

+ correct glycosylation patterns

+ large amounts possible

+ easier downstream processing

– contamination

– ethical issues

– spontaneous mutations

– animal facilities and personnel required

in vitro production:

+ correct glycosylation patterns in mammalian cells

+ faster timelines

+ avoidance of animal facilities

+ no ethical issues

+ increased flexibility

+ full versatility of recombinant methods (Ab fragments, bispecific Abs)

– specialized personnel and equipment

– lower Ab concentrations in media

Employing modern molecular biology methods, in vitro recombinant antibody production brings numerous key advantages to the table: short timelines, high yields, flexibility regarding full length/ fragments and target antigen.

The largest disadvantages are the required skilled personnel and equipment, including bioreactors that allow for on-scale production.

While these have been serious drawbacks for several years, innovative companies established themselves as contract manufacturing organizations and now offer reliable in vitro recombinant antibody production services.

Switzerland based company evitria solved many of the issues associated with in vitro antibody production and produces recombinant antibodies expressed in CHO cells within 5 weeks.