From sequence to antibody in 5 weeks – with the highest quality standards

Low levels of endotoxin <1EU/mg

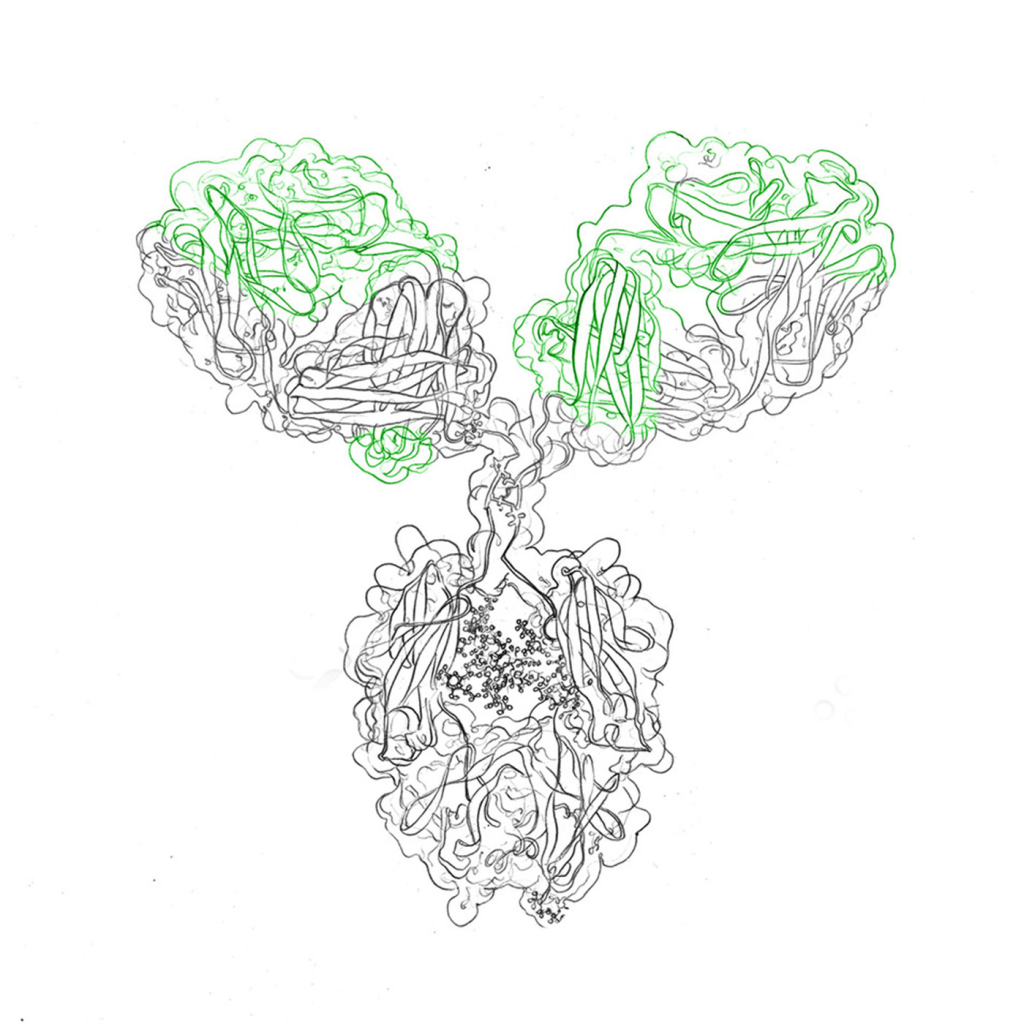

Polyclonal antibodies (pAb) are a crucial tool in the fields of research and diagnostics, with a wide range of applications in immunology, biochemistry, and molecular biology. Polyclonal antibodies are produced by immunizing animals with a specific antigen, resulting in the production of a heterogeneous mixture of antibodies that can recognize different epitopes on the antigen.

This article will provide a comprehensive guide to polyclonal antibody production (pAb production), outlining the steps involved in the process, discussing the advantages and disadvantages of using polyclonal antibodies, and exploring the alternatives to polyclonal antibody production, including recombinant antibody production.

Polyclonal antibodies are a type of antibody produced by immunizing animals with a specific antigen. They are generated by multiple B-cell clones, resulting in a heterogeneous mixture of antibodies that recognize different epitopes on the antigen. Polyclonal antibodies have a high affinity and specificity for the antigen, making them effective tools in research and diagnostics.

The production of polyclonal antibodies typically involves immunizing animals such as rabbits, mice, rats, guinea pigs, goats, or sheep with an antigen. The animal’s immune system responds by producing antibodies, which can be collected from the animal’s serum. Polyclonal antibodies are commonly used in applications such as Western blotting, ELISA, and immunohistochemistry due to their ability to detect multiple epitopes on the same protein.

Subscribe to our Newsletter

Get all the latest updates, and learn about our advancements in antibody production.

Subscribe now

While polyclonal antibodies have many advantages, such as their high specificity and versatility, they also have some disadvantages. The heterogeneity of polyclonal antibodies can result in batch-to-batch variability, and the use of animals for antibody production raises ethical concerns. As a result, there has been growing interest in developing alternative antibody production methods such as recombinant antibody technology.

Despite the potential limitations, polyclonal antibodies remain an essential tool for many researchers and diagnostic laboratories. Understanding the basics of polyclonal antibody production is crucial for choosing the right antibody for a given application.

Read more: In vivo antibodies

The production of polyclonal antibodies involves several key steps, including immunization, blood collection, serum preparation, and antibody purification.

The first step in polyclonal antibody production is antigen preparation. The target antigen can be a purified protein, a peptide, or a mixture of proteins, depending on the application. The purity and quality of the antigen are critical to the success of the antibody production process.

Immunization is the second step in polyclonal antibody production, where animals are injected with the antigen of interest. The antigen is typically mixed with an adjuvant such as Freund’s adjuvant to enhance the immune response. The adjuvant helps to stimulate the animal’s immune system, resulting in a stronger antibody response.

After immunization, the animal’s blood is collected to obtain serum containing the polyclonal antibodies. The serum is then subjected to an initial screening test to determine the titer of the antibodies. The antibody titers is a measure of the concentration of antibodies in the serum and reflects the strength of the antibody response.

The next step is antibody purification, which involves isolating the specific antibodies of interest from the serum. This can be done using a variety of methods such as protein A or protein G affinity purification.

Affinity purification involves using a column containing the antigen or a related molecule to selectively bind the antibodies with the highest affinity. This results in a highly enriched population of polyclonal antibodies that can be used in various applications.

The final step in polyclonal antibody production is the characterization of the purified antibodies. This involves determining the specificity and sensitivity of the antibodies to the antigen of interest. Immunoglobulin G (IgG) is the most commonly used class of antibodies in research and diagnostics due to their high affinity and specificity.

While polyclonal antibodies have many advantages, including fast and cheap production, as well as high specificity and versatility, they also have some limitations that should be considered when choosing an antibody for a specific application.

One of the main disadvantages of polyclonal antibodies is batch-to-batch variability. Since polyclonal antibodies are generated by multiple B-cell clones, the resulting antibodies can vary in their affinity and specificity for the antigen. This variability can result in inconsistencies in experimental results, which can be problematic in certain research applications.

Another limitation of polyclonal antibodies is the potential for cross-reactivity. Since polyclonal antibodies are generated from animals that have been exposed to the antigen of interest, they can sometimes recognize other proteins or molecules that are structurally similar to the antigen. This can result in false positive or false negative results in certain assays.

The use of animals for polyclonal antibody production also raises ethical concerns. The process involves immunizing animals and collecting their serum, which can be stressful and painful for the animals. Additionally, the use of Freund’s adjuvant can cause local inflammation and discomfort at the injection site.

Finally, the purification of polyclonal antibodies can be challenging, as the affinity purification process may not result in complete isolation of the desired antibodies. This can result in the presence of impurities in the purified antibody preparation, which can interfere with experimental results.

Despite these limitations, polyclonal antibodies remain a popular choice for many researchers and diagnostic laboratories due to their versatility and availability. However, for certain applications where high specificity and consistency are critical, alternative antibody production methods, such as recombinant antibody technology, may be a better choice.

Monoclonal antibodies (mAbs), in contrast to polyclonal antibodies, are produced by a single B-cell clone and are therefore highly specific for a single epitope on the antigen. This high specificity makes monoclonal antibodies ideal for certain applications, such as diagnostic assays and targeted therapies.

Monoclonal antibody production can be done using hybridoma technology, which involves fusing a myeloma cell with a B-cell that has been stimulated with the antigen of interest. This results in the production of a homogeneous population of antibodies that all recognize the same epitope on the antigen.

Recombinant production of monoclonal antibodies offers several advantages over traditional hybridoma technology. Recombinant monoclonal antibodies can be produced in large quantities in vitro using a cell line without the need for animal immunization or hybridoma fusion. This not only reduces ethical concerns related to laboratory animal use, but also allows for greater consistency and reproducibility between batches of antibodies.

Recombinant monoclonal antibodies can also be engineered to have specific properties, such as increased stability or reduced immunogenicity, that make them more suitable for certain applications. Additionally, recombinant production allows for the use of non-immunoglobulin scaffolds, such as antibody fragments or synthetic binding proteins, which can be designed to have specific binding properties and can be easier to produce than full-length antibodies.

Overall, while polyclonal antibodies have their advantages, recombinant monoclonal antibodies offer several benefits for certain applications. Their high specificity, consistency, and reproducibility make them ideal for use in diagnostic assays. Recombinant production allows for greater control over antibody properties and production, and in vitro cell line expression enables high titer production.

Low levels of endotoxin <1EU/mg

Polyclonal antibodies (pAbs) are well known for their robustness and epitope diversity, which makes them well suited for use in diagnostics or other assays. However, they suffer from batch-to-batch variability, or complete loss of supply when the host animal dies. Using polyclonal reagents risks costly revalidation efforts for every batch, and the eventual need to start R&D efforts from scratch when supply runs out. A well-selected cocktail of monoclonal antibodies (mAbs) can recapitulate the binding activity of a pAb. But R&D efforts to generate new mAbs that work as well as an established pAb often disappoint.

Immunoassays that rely on monoclonal antibodies (mAbs) derived from hybridomas are also prone to supply chain risk. Hybridomas often drift, die, or produce unwanted additional chains eventually leading to immunoassays with changed behaviors. By producing recombinant monoclonal antibodies (rAbs), IVD manufacturers can ensure a constant and reliable supply of critical reagents.

evitria offers customized recombinant antibodies transiently expressed in cho cells. CHO cell expression enables production of high quality antibodies within 5 weeks from sequence to antibody. evitria has experience of over 20,000 antibodies purified and supports customers in research and industrial applications worldwide.

Polyclonal antibodies are produced by immunizing an animal with an antigen, collecting the serum containing the antibodies, and then purifying the antibodies. Monoclonal antibodies are produced by fusing myeloma cells and B-cells to create hybridoma cells that produce identical antibodies.

Polyclonal antibodies are produced by immunizing an animal with an antigen, collecting the serum containing the antibodies, and then purifying the antibodies.

The most common source of polyclonal antibodies is serum collected from animals that have been immunized with an antigen.

An advantage of monoclonal antibodies over polyclonal antibodies is that they have a defined specificity and can be produced in unlimited quantities.